Success Story Powered by New York MEP Regional Center Member “Center for Economic Growth”

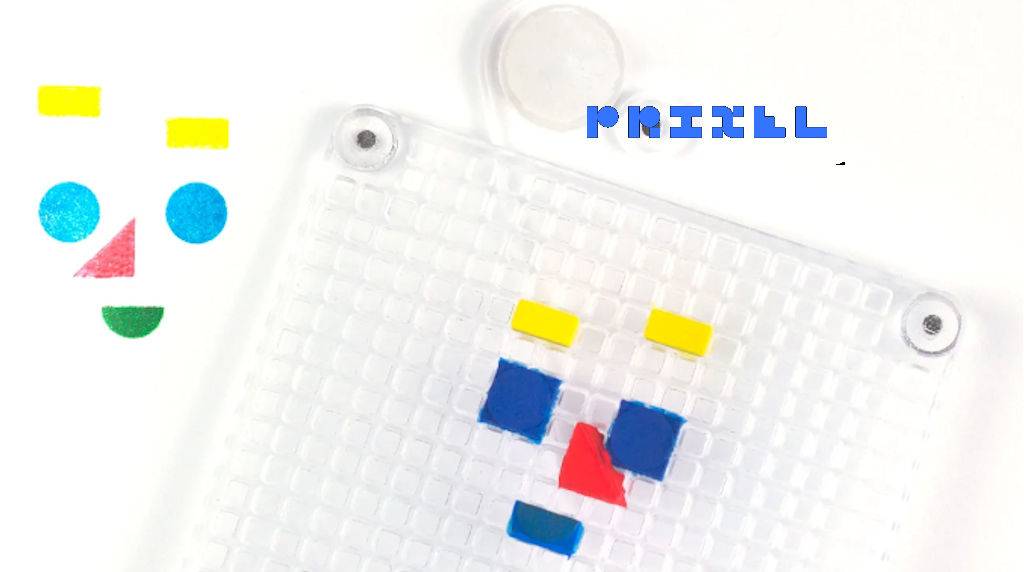

Prixel Press is a Hudson, NY based toy manufacturing start-up that makes customizable printmaking kits. The kits are make up of 2 press grids which hold rubber shapes arranged as the user sees fit. Then dabbing on some ink to the shapes, you press the kit onto the surface you a printing on to leave up to a 4″ x 4″ image. The kit is the brainchild of Brandon Gamm, who made the first prototype of the Prixel Press in 2011 while working as a graphic designer. The original design was built from laser-cut rubber pieces glued to lego. Over the next 7 years he iterated on the design with the goal of launching a business from the idea. He incorporated the company in 2018.

Shortly after incorporating the company, Gamm visited the Troy, NY based Tech Valley Center of Gravity (TVCOG) maker space and started using their laser cutter to cut the plastic trays and the and vacuum former to mold them. He uses a desktop CNC machine at his home office to produce molds for casting the 544 unique PRIXEL pieces included with the kit.

Brandon wanted to move beyond the prototype stage to a mass-manufactured product. In order to do this, he turned to the Center for Economic Growth (CEG), a member of the New York Manufacturing Extension Partnership (MEP) and the MEP National Network along with the TVCOG. Leveraging the manufacturing expertise of CEG and TVCOG, an advisory committee was formed that met monthly and an engineer-in-residence (Troy Fischer, a 28-year veteran inventor with Toy/Game experience) was assigned. This helped Gamm avoid typical mistakes in the industry and guided his journey of making one-off kits to a building a dozen of them at a time. The relationship with TVCOG has also opened the door to a network of people who can help him find contract manufacturers to mass produce the components of the kit and help deal with the logistics of multiple parties involved in the process.

I always wanted to turn this toy invention into a business, and the Tech Valley Center of Gravity and Center for Economic Growth helped me do that because they have the tools you need for prototyping and can help with scaling up production. The Tech Valley Center of Gravity’s Manufacturer Incubator Program kept me on a path to commercialization, saved me from mistakes toy entrepreneurs frequently encounter, and helped me make connections that further helped me develop the business.

- A disciplined approach devised to move from prototype to mass production

- Built connections to help scale the business itself

Read the full story on the NIST website here.